Resin Transfer Molding (RTM)

Fiber-reinforced composites, molded via Resin Transfer Molding (RTM), are well suited for ultra-strong yet lightweight parts exposed to environmental extremes. Low viscosity RTM polymers like polyester, vinyl ester, and epoxies are specially engineered to provide excellent mechanical properties in all applications.

The closed-molding process of thermoset materials known as Resin Transfer Molding (RTM), was utilized and perfected by Osborne scientists and engineers in the 1970s, before the industry even had a name for it. With more than 50 years of experience in RTM manufacturing, trust Osborne to provide turnkey guidance of your next project: from concept to prototype to final product, and from patterns and molds to final inspection.

Overview

Resin Transfer Molding (RTM) is time-tested and proven closed-molding process. At Osborne, we tailor our RTM materials to match a wide range of design criteria, including specifications for:

- Hardness

- Color

- Dielectric Strength

- Flame Resistance

- Smoke Suppression

- Corrosion Resistance

- Impact Resistance

- Abrasion Resistance

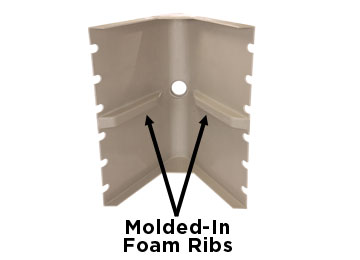

The RTM manufacturing process is well suited for medium to large size parts in complex shapes and designs. Parts with thickness from 0.100-inch (2.5 mm) to 2.000-inches (50.8 mm) and with a surface area greater than 2-ft2 (0.2-m2) are made successfully. Internal molding of reinforcing brackets, stiffening ribs and bosses, and variable cross-sectional thicknesses reduce secondary manufacturing operations and create an ultra-strong part.

RTM is widely used for:

- Large truck and bus body panels

- Hoods and roofs for heavy machinery

- Instrumentation housing

- Equipment parts in agriculture

Benefits

Ultra-strong fiber-reinforcement in Resin Transfer Molding provides the structural strength in a molded product, providing excellent properties in environmental extremes. Additionally, RTM molding at Osborne can be customized based on specific application requirements. This means Osborne is not restricted to molding “off-the-shelf” resin formulations. Other RTM benefits include:

- Aesthetic surface quality and finish

- Wide range of option for reinforcements

- Exact dimensional tolerances for large, complex shapes

- Zero air entrapment within parts

- Low environmental impact

- Low capital investment and tooling flexibility

Low reaction temperatures and injection pressures in RTM offer flexibility in tooling, including the use of low-cost composite tools, reducing up-front investment costs when compared to injection molding or compression molding tooling. Superior quality and efficiency quickly repay the added invest in Osborne-made RTM molds when compared to simple open molds. Osborne can match production capacity to your largest projects.

- Mold part sizes from 1 sq-ft to over 100 sq-ft

- Multiple RTM production lines

- Numerous RTM presses of all sizes

- In-molding coating

- Directed-fiber preforming machines

- Secondary finishing operations

All together, these advantages make RTM an economical choice for medium to large parts in low to medium volumes.

Definition

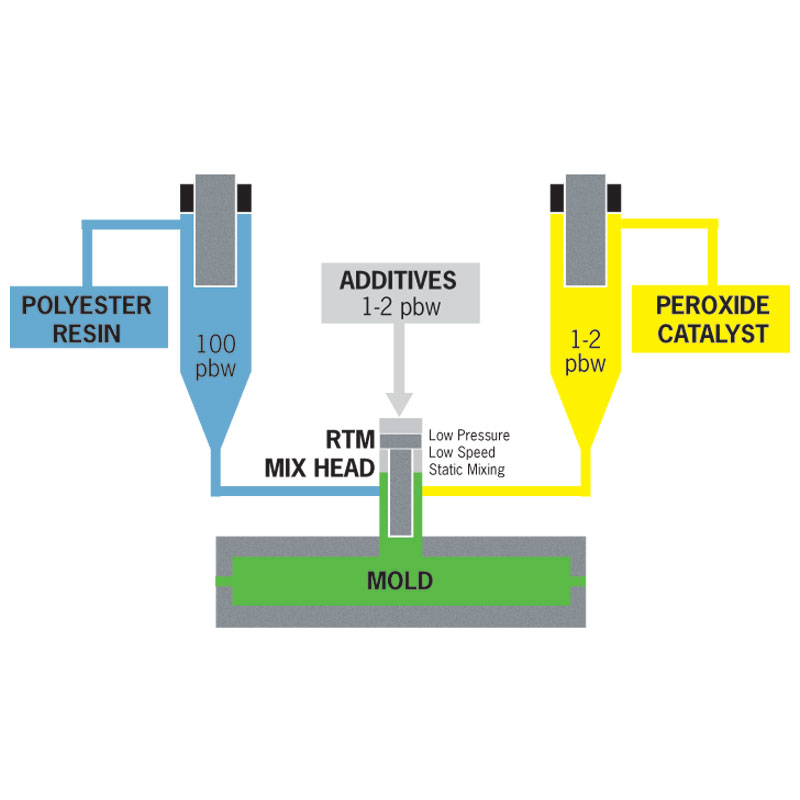

Resin Transfer Molding (RTM) is commonly referred to as liquid molding. With this process, a resin is mixed with a catalyst (hardener) and injected into a mold that contains dry fibers, such as fiberglass. A static mixer regulates the ratio of polyester resin to catalyst. Usually a ratio of 100:1 of resin to catalyst is used. The mixture is then injected at a low pressure of approximately 5 psi into the mold. The reaction time is usually minutes.

Equipment

We operate and maintain a full range of RTM molding equipment, providing our customers with the assurance and confidence that their project will be completed on time and on budget.

The tooling used with RTM molding offers special advantages, as well, including:

- An efficient, natural transition from prototype to high-volume production.

- A low-cost path to commercial parts compared to high-cost tooling for compression molding.

- Quick repayment of the added investment in RTM compared to simple open molds via superior quality and efficiency.

Our RTM equipment includes:

- 17 RTM production lines

- 13 RTM production machines

- Five gel-coat application machines for in-mold coating

- Numerous RTM presses and mold handling devices

- Two directed-fiber preform machines

Osborne also offers:

- Completely equipped secondary trimming and finishing department.

- Two (2) 5-axis CNC routers with twin beds, with a maximum capacity (x,y,z) of 12-ft x 6-ft x 48-ft.

- Structural bonding and assembly services.

- Completely equipped quality assurance laboratory.

FAQs

RTM parts are well known for their durability, excellent strength-to-weight ratio, and resistance to high heat. These properties make parts molded with RTM a great alternative to those manufactured with metal. High reinforcing content – up to as much as 50%+ – provides the structural strength, quality, and durability, especially in parts with thick walls or cross-sections. Many thermosetting RTM materials can also withstand extremely high temperatures without degradation or deformation, and can even be custom formulated for specific properties like abrasion resistance, UV resistance, and even smoke resistance.

Investment in tooling for RTM is mostly based on part size and geometry. The larger the tool, the higher the investment. However, since RTM is a low-pressure molding process, composite or “soft” tools can be utilized, as opposed to high-cost steel or nickel. Production volumes also plays a part in what type of tool should be used, but the low to medium volumes typical of RTM, allow for the use of low-cost composite tools.

Although Resin Transfer Molding (RTM) and Compression Molding are similar processes, they differ in the way the material is processed within a mold. With RTM, a structural preform (typically fiberglass) is manually placed within a closed mold before liquid resin is pressurized and injected through a small opening into the mold. With Compression Molding, material is manually placed within a mold cavity before pressure is applied to the entire mold to form the final part shape.

Many factors, including the resin color or pigment, the glass content, and use of in-mold coatings affect the appearance of print-through on RTM parts. When aesthetic appearance is important and glass print-through is undesirable, a light layer of fiberglass veil can be applied to the preform to minimize visible glass in a finished part. Gel-coat can be applied directly onto a mold cavity before resin is injected, providing a smooth and glossy surface finish with little to no visible print-through.

Resin systems with RTM can be custom pigmented to match virtually any color, including the color of the gel coat or in-mold coating itself. If a part incurs surface scratches or slight damage, the underlying resin matches the gel coat, minimizing any defects to surface appearance.

Yes, Vacuum-Assisted Resin Transfer Molding (VARTM) or Light Resin Transfer Molding (LRTM) is a variation of standard RTM molding. Unlike traditional RTM, VARTM or LRTM utilizes processing tools similar to open molding, owing to its minimal internal cavity pressure. Typical tools include one rigid mold half or “A-side,” and a semi-flexible upper mold half or “B-side.” Internal mold pressures are less with VARTM or LRTM because a vacuum is used to pull the liquid resin through the reinforcing preform. Tooling costs are less costly with VARTM or LRTM, but only one side of a part (the “A-side”) offers aesthetic surface appearance. Additionally, VARTM or LRTM cannot meet the production rates of traditional closed molding processed like RTM owing to longer processing times and less durable tooling.

Case Studies

Gel-Coated Parts

Aerial Lift Platforms (Aerial Lift Buckets)

Molding Process: Resin Transfer Molding (RTM)

Material: FRP Composite

Color: White, yellow and misc. custom colors

Finish: Gel-coat color-matched to composite substrate

Secondary Operations: Structurally bonded accessories

Part Weight: Multiple parts from 55 to 120 lbs.

Innovative Answers:

- Osborne engineering reduces weight of aerial platforms by 30% or more, while increasing strength and safety

- Structurally bonded steps and mounting plates and special modifications for hundreds of optional designs delivered just-in-time (JIT), cuts inventory and boosts assembly efficiency

- In-mold gel coat enables color flexibility and eliminates secondary painting operations

Forklift Body Parts

Molding Process: Resin Transfer Molding (RTM)

Material: FRP composite

Color: Black

Finish: Black gel coat

Part Weight: Parts from 6 to 35 lbs.

Innovative Answers:

- FRP composite to resist battery acid corrosion

- High-strength FRP structure with engineered reinforcement at key stress locations

- Attractive, easily cleaned, and durable finish

Water Sampler Housing Components

Molding Process: Resin Transfer Molding (RTM)

Parts Molded: Body, base, insulated door, instrument adapter, and top cover

Material: FRP Composite

Color: Gray

Finish: Gray gel coat

Part Weight: Parts from 6 to 27 lbs.

Innovative Answers:

- Corrosion-resistant FRP components replaces painted steel

- Foam-core FRP door combines insulation and structure

- Integrated hinge reduced assembly time

- Consolidation of multiple parts cuts parts inventory and eliminates assembly labor

Medical Bed Tub

Molding Process: Resin Transfer Molding (RTM)

Parts Molded: Tub

Material: FRP composite with metal components and molded inserts

Color: Teal

Finish: Teal gel coat

Part Weight: 130 lbs.

Innovative Answers:

- Professional appearance with superior strength

- Elimination of secondary painting with in-mold sanitary gel coat

- Reduction of customer’s final assembly time by sub-component assembly

Specialty Medical Chairs

Molding Process: Resin Transfer Molding (RTM)

Material: FRP Composite

Color: White, gray, tan

Part Weight: Parts from 25 to 35 lbs.

Innovative Answers:

- Designed to maintain structural integrity, while transporting patients in and out of warm saline solution

- Water tight inserts and composite material give long service life

- Attractive and durable medical application

- Low-cost composite tooling made it feasible to offer multiple design options

Paint-Ready Parts

Bus & Vehicle Window Panels

Molding Process: Resin Transfer Molding (RTM)

Material: FRP Composite

Color: Grey

Finish: Sandable gel-coat surface prepared for painting by Osborne

Part Weight: Multiple parts from 7 to 15 lbs.

Innovative Answers:

- FRP composite meets stringent Docket 90 tests for flame spread and smoke density

- Sandable gel-coat primer gives a paint-ready surface

- Trimmed to tight tolerances with CNC router for precise fit with glass inserts

Medical Instrument Covers

Molding Process: Resin Transfer Molding (RTM)

Parts Molded: Three models of instrument covers

Material: FRP Composite

Color: Gray

Finish: Sandable Gel coat

Part Weight: Multiple parts from 40 to 60 lbs.

Innovative Answers:

- Attractive, streamlined styling for professional market

- Precision fit for instrument controls and diagnostic screens

- Fire-retardant and smoke-suppressant RTM resin formulation to meet international safety and RoHS standards

- Paint-ready surface

- On-demand delivery helps customer meet tight delivery schedules with minimum parts inventory

Heavy Machinery Covers

Molding Process: Resin Transfer Molding (RTM)

Material: FRP Composite

Color: Gray

Part Weight: Parts from 20 to 25 lbs.

Innovative Answers:

- FRP engine covers maintain dimensional stability and strength, when exposed to high engine temperatures.

- Engineered for strength at fastening points to withstand frequent impact

Pigmented Resin Parts

Truck & Tractor Fan Shrouds

Molding Process: Resin Transfer Molding (RTM)

Material: FRP Composite

Color: Black

Part Weight: 5 lbs. each

Innovative Answers:

- Multi-part shroud maintains precise orifice-radius after assembly

- Holes and slots are cut after molding to tight tolerances using 5-axis CNC routers

- Rigidity and minimal thermal expansion is assured by FRP composite design

- Molded to strict military specifications

- Low-cost composite RTM tooling keeps capital investment low

Cotton Picker Industrial Blower Housing

Molding Process: Resin Transfer Molding (RTM)

Parts Molded: Blower Housing and Cover

Material: FRP composite with pre-molded reinforcing cores

Color: Emerald green

Part Weight: 56 and 9 lbs.

Innovative Answers:

- Engineered and molded to tight tolerances to maximize airflow

- Abrasion-resistant composite formulated by Osborne to withstand harsh environments

- Combination of appearance, durability, and performance meet or exceed all customer and application requirements

Water Treatment Concrete Forms

Molding Process: Resin Transfer Molding (RTM)

Material: FRP composite with reinforced foam cores

Color: Gray

Part Weight: 70 lbs.

Innovative Answers:

Converting concrete water-treatment structures to FRP composite components delivers:

- Increased structure life and greatly reduced maintenance costs

- Quick, easy installation with less labor and expensive machinery

- Less transportation and handling cost for lightweight FRP components

Industrial Cab Panels & Covers

Molding Process: Resin Transfer Molding (RTM)

Parts Molded: Cab Roof, Front Panel, and Doors

Material: FRP Composite

Color: Yellow

Weight: Various

Innovative Answers:

- Uniform wall thickness and dimensional tolerance solved problems with fit and finish

- Precise molding made for easy installation of prefabricated aluminum windows

- Accurate molding to specified tolerances, gives door hardware proper fit and function

- Strategically incorporated foam core adds styling and functional strength

- Low-cost pigmented resin eliminates secondary painting operation

Light-Armor Military Case

Molding Process: Resin Transfer Molding (RTM)

Parts Molded: Battery Case & Cover

Material: FRP Composite

Color: Natural (Painted Olive Green by Contractor)

Part Weight: 7 and 10 lbs.

Innovative Answers:

- Built to exacting military specifications

- Ultra high-strength glass reinforcement

- Flame-resistant composition

Hog and Pig Feeders

Molding Process: Resin Transfer Molding (RTM)

Parts Molded: Hopper Lid, Hopper Top, Hopper Bottom, and Trough

Material: FRP Composite

Color: Green

Part Weight: Parts from 5 to 50 lbs.

Innovative Answers:

- Corrosion and abrasion resistant composite provide long-term durability in a harsh livestock environment

- Interchangeable parts are possible because of tight control of tooling and process

Under-Body Electric Animal Heating Mats

Molding Process: Resin Transfer Molding (RTM)

Material: FRP Composite

Color: Orange

Part Weight: Parts from 7 to 45 lbs.

Innovative Answers:

- Corrosion and abrasion resistant composite provide long-term durability in a harsh livestock environment

- Single molded piece with embedded heating element resists moisture entry

- Flame-resistant resin mix to prevent barn fires