pDCPD Molding

Polydicyclopentadiene (pDCPD) is an engineered thermoset polymer possessing an excellent combination of chemical and corrosion resistance, stiffness, impact strength, and heat resistance. pDCPD delivers the molding flexibility of a thermoset, but with characteristics similar to expensive engineered thermoplastics.

Osborne has over 20 years of experience molding pDCPD (polydicyclopentadiene) and molds parts using a range of DCPD resins via Reaction Injection Molding (RIM) to meet your most demanding part requirements. We bring technical expertise in DCPD chemistry, a fully equipped and highly trained staff of DCPD specialists, and the skills of dedicated craftsmen to help transform your engineered concept into reality.

Overview

pDCPD is prepared by polymerizing low-viscosity DCPD monomer in low-pressure processes that enable the use of low-cost molds and fast cycle times. Low-viscosity means that pDCPD gives excellent replication of surface features for aesthetically demanding applications. Additionally, pDCPD gives superior paint adhesion and durability for appearance parts. pDCPD is used on numerous other applications wherever large, tough, corrosion-resistant, and aesthetically pleasing appearance is required.

The design freedom of pDCPD has virtually no limitation on part size or weight. Parts with thickness from 0.100-inch (2.5 mm) to 12-inches and with a surface area from 1-ft2 (0.1-m2) to 140-ft2 (13-m2) are made successfully. Parts with variable wall thickness and molded stiffening ribs are possible. Molded bosses and fasteners reduce secondary assembly operations. Good adhesion and machining quality extend the usefulness of pDCPD parts.

pDCPD is widely used for:

- Large truck and bus body panels

- Instrumentation housing

- Equipment parts in agriculture

- Large waste containers

- Recreation parts

- Domestic wash basins and shower stalls

- Construction equipment parts

- Water treatment equipment

- Conveyor trays

- Fan shrouds

- Shipping containers

- Septic tanks

- Corrosion-resistant chemical process equipment

Benefits

The benefits of molded polydicyclopentadiene (pDCPD) include parts with:

- High tensile strength

- High impact strength

- Moderate flexural properties

- High heat distortion temperature

- Excellent corrosion resistance

The flexibility of adding several additives can be added to the liquid DCPD monomer to create specialized resin formulations that give the final polymerized material a wide range of mechanical properties and characteristics including:

- Flexibility

- Rigidity

- Flame retardance

- Pigmentation

- Abrasive resistance

Corrosion resistance is another beneficial characteristic of pDCPD, which has been used in the chlor-alkali industry for more than 20 years.

Definition

Thermosets like pDCPD are distinguished from thermoplastic materials, the other main group of plastics, because, unlike thermoplastics which revert back to liquid form under excessive heat, thermosets will remain in a post-cured form. pDCPD and other thermosets resist melting because of the process by which they’re created: Two dissimilar liquids are mixed together, creating high temperatures that foster cross-linking between molecular chains. This cross-linking contributes to thermosets’ heat resistance.

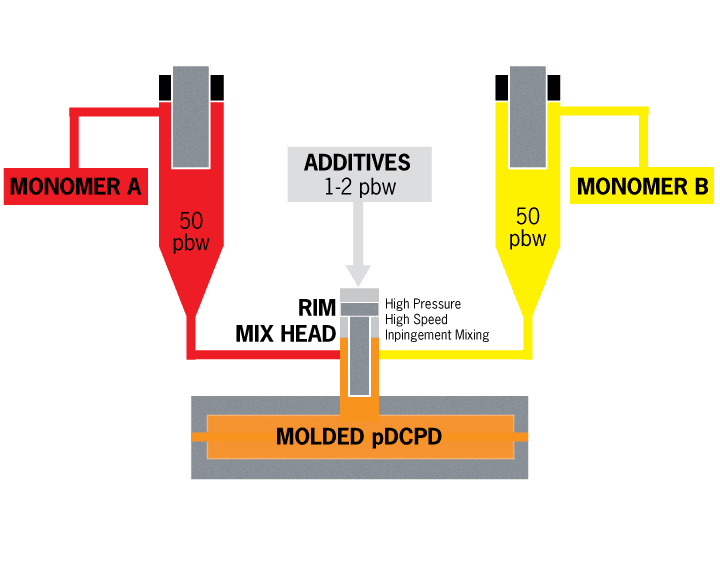

RIM-molded pDCPD parts are created through a process that begins when two liquid reactants – an isocyanate component and a polyol resin mixture – are held in separate tanks at an elevated temperature with agitators. These liquids are fed through supply lines at high pressure to the mixhead.

When the injection begins, valves open in the mixhead and the liquids enter a chamber in the mixhead at high pressures (usually between 1,500 and 3,000 psi) and high speeds. Here they are mixed by high-velocity impingement. From the mix chamber, the mixed liquid flows into the mold at atmospheric pressure and undergoes an exothermic chemical reaction, forming a polymer in the mold.

Reaction time is usually expressed in seconds. For extremely large parts the reaction time can be extended to allow for proper filling of the mold.

Dicyclopentadiene (DCPD), a liquid monomer, is catalyzed by an active metal component via the ring opening metastasis polymerization (ROMP) process. The monomer and catalyst can be mixed by hand or by Reaction Injection Molding (RIM).

We use two different metal-activated catalyst systems that allow for unique mechanical properties, which are customizable for given projects. The liquid DCPD monomer also can be combined with several additives to create specialized resin formulations.

Equipment

Osborne’s pDCPD molding via reaction injection molding (RIM) includes equipment and low-cost composite or aluminum RIM molds that offer the production flexibility you need for your most demanding projects.

We’re pleased to run a wide range of RIM molding equipment, including:

Reaction Injection Molding (RIM) Machines

Lance Injection Unit

- Capacity: 180 lb/min

- Components: 2

- Ratio: Variable

- Mixheads: 1

Gusmer K-RIM 60

- Capacity: 60 lb/min

- Components: 2

- Ratio: 1:1 w/variable adapter

- Mixheads: 2 or 3 component

Gusmer Delta-RIM 80

- Capacity: 80 lb/min

- Components: 2

- Ratio: Variable

- Mixheads: 2

Gusmer FF-1600 Foam Proportioner

- Capacity: 16 lb/min

- Components: 2

- Ratio: 1:1

- Mixheads: 2

Gusmer Delta-RIM 80

- Capacity: 80 lb/min

- Components: 3

- Ratio: Variable

- Mixheads: 2

Accumetric Meter-Mix

- Capacity: 1.2 lb/min

- Components: 2

- Ratio: Fixed

- Mixheads: 1 (Mechanical)

Admiral 2000 – 2 HP

- Capacity: 300 lb/min

- Components: 2

- Ratio: Variable

- Mixheads: 1

Reaction Injection Molding (RIM) Presses

Cincinnati Milacron 90T WL

- Capacity:90 ton

- Platen:48 x 108-in, tilting

- Open/shut height:72-in / 36-in

- Operation:Manual

Cincinnati Milacron 90T WL

- Capacity:45 ton

- Platen:48 x 79-in

- Open/shut height:84-in / 24-in

- Operation:Manual

Cincinnati Milacron 90T WL

- Capacity:90 ton

- Platen:48 x 108-in, tilting

- Open/shut height:72-in / 36-in

- Operation:PIC Automatic

Osborne-built press

- Capacity:150 ton

- Platen:60 x 108-in

- Open/shut height:56-in / 8-in

- Operation:Manual

Two (2) Cincinnati Milacron 75T WL

- Capacity:75 ton

- Platen:36 x 90-in, tilting

- Open/shut height:54-in / 33-in

- Operation:PLC Auto or Manual

- Frame Rotation Angle:0 to 90 degrees

Osborne-built press

- Capacity:45 ton

- Platen:40 x 56-in

- Open/shut height:47-in / 8-in

- Operation:Manual

FAQs

Yes. The DCPD polymers used at Osborne can be custom-pigmented to match virtually any color. Parts can also be secondarily painted or an in-mold paint can be used that chemically bonds to the surface of the part. Because some DCPD materials are affected by UV light, parts exposed to UV should either be painted or UV-inhibitors used in the molding process.

DCPD or pDCPD (polydicyclopentadiene) is a polymer that delivers the benefits of a thermoset with characteristics similar to those of highly engineered thermoplastics. The material provides an excellent combination of stiffness, impact strength, heat deflection temperature, and corrosion resistance. While other materials used in RIM, like polyurethanes, are also thermosets and provide outstanding corrosion resistance, these materials have a wide range of flexural properties ranging from soft and flexible to hard and rigid. Whatever the application, there is a RIM material at Osborne to meet or exceed the toughest product requirements.

pDCPD is already widely used across a variety of industries where ultra-tough, damage/impact-resistant, lightweight, and corrosion-resistant parts are required. Parts for the transportation industry, like bumpers, fascias, and wheel arches for buses and trucks; the construction industry, like body panels, hoods, deflectors, and bumpers on heavy machinery and construction equipment; and the agriculture industry, like engine hoods and fenders for tractors and combines, make up the most popular industries for DCPD materials today. Osborne-molded DCPD parts are continually expanding into other markets where metal or injection-molded thermoplastics are unsuitable.

DCPD resins are processed using closed molds via Reaction Injection Molding (RIM) which provides smooth, non-porous, aesthetic surface finishes. The molds are clamped together using hydraulic presses. DCPD presses are not required to handle high pressures found in other molding methods like sheet molding compound (SMC) or thermoplastic injection molding. Therefore, most tooling for pDCPD is made from machined or cast aluminum, which is considerably less expensive than the hard steel tools required for thermoplastic molding.

Depending on part size and geometry, composite tooling can successfully be used for small production runs and prototyping. Typically, final production parts are molded in cast or machined aluminum molds.

Case Studies

Portable Lighting Equipment Enclosures

Molding Process: Reaction Injection Molded (RIM)

Material: Telene® pDCPD

Color: Molded black, secondarily painted

Part Weight: 23 lbs.

Innovative Answers:

- DCPD replaces steel doors prone to rusting and denting

- Enhances aesthetic qualities with smooth and impact-resistant surface

- Part consolidation eliminates multiple parts and reduces overall weight

- pDCPD provides thermal stability in especially hot or extremely cold weather

Water Clarification Screen

Molding Process: Reaction Injection Molded (RIM)

Material: Telene® pDCPD

Color: Black

Part Weight: 21 lbs.

Innovative Answers:

- DCPD replaces an expensive stainless steel skimmer in harsh water treatment application

- Light weight material reduces installation time and shipping cost

- Part consolidation eliminates multiple parts and welded joints

- Corrosion resistance equivalent to stainless steel

Vehicle Instrument Panels

Molding Process: Reaction Injection Molded (RIM)

Material: Rutene® PDCPD composite

Color: Molded yellow, painted black

Part Weight: 2 lbs.

Innovative Answers:

- Geometry and surface details are accurately reproduced with Rutene® composite

- Demanding impact resistance, fire retardance, and dimensional stability requirements are accurately met with DCPD

- Surface easily painted to match OEM specifications

Corrosion-Resistant Fittings

Molding Process: Reaction Injection Molded (RIM)

Material: Telene® pDCPD

Color: Molded black, secondarily painted

Part Weight: 10 lbs.

Innovative Answers:

- Telene® replaces metal spool for longer life in a harsh chemical environment

- Molded-in threads eliminate secondary operations

- DCPD can be accurately molded in very thick cross sections without cracking

Chlor-Alkali Cell Tops

Molding Process: Reaction Injection Molding (RIM)

Parts Molded: Cell Tops

Material: Telene® pDCPD

Color: Various

Part Weight: Up to 1000 lbs.

Innovative Answers:

- pDCPD material is durable and temperature resistant in corrosive electrochemical conditions

- Reaction Injection Molding (RIM) allows for large part production (1000 lbs)

- Secondary operations include site gauges and viewing ports, necessary for immediate installation

- Strict quality management control

Construction Machine Covers

Molding Process: Reaction Injection Molded (RIM)

Material: Rutene® pDCPD Composite

Color: Yellow, secondarily painted

Part Weight: 35-45 lbs.

Innovative Answers:

- Rutene® pDCPD offers superior impact resistance

- Lighter weight than Fiberglass Reinforced Plastic, making hoods easier to manage

- Typical sink marks (phantom lines), common with molded ribs, are eliminated with DCPD Rutene formulation giving a high quality part surface

Corrosion-Resistant Pipe Fittings

Molding Process: Reaction Injection Molded (RIM)

Material: Rutene® pDCPD

Color: Red and Black

Part Weight: 5 lbs.

Innovative Answers:

- Built in flange and threaded bolt holes combine parts and reduces installation time

- DCPD material has superior durability in a chemically corrosive environment