Reaction Injection Molding (RIM)

RIM polymers at Osborne are engineered to produce parts ranging from soft and flexible to hard and rigid. Ranging from elastomeric urethanes to highly engineered DCPD, the materials used in RIM are perfect for converting heavy, rust-prone metal parts to lightweight, corrosion-resistant components.

With more than 20 years of experience in RIM, custom molded parts at Osborne are manufactured competitively, even at low production volumes. Low cost composite and aluminum tooling and specialized production methods mean our RIM molding services can compete economically with other processes, yet offer outstanding material properties not found in traditional injection molding.

Overview

Osborne’s durable, low-cost composite RIM molds offer production flexibility early in the life of your project, allowing you to convert to high-speed metal tooling for high-volume production when your market dictates. Osborne’s specialized RIM molding process allows you to:

- Inexpensively market test your new concepts

- Keep investments tied to market success

- Increase to full production as sales grow

- Profit from low- and medium-volume RIM production and from long mold service life

With the ability to accommodate larger RIM parts and tougher specifications, Osborne routinely engineers and manufactures large, heavy, high-performance parts from 2 lbs to over 1000 lbs. The platen size and tonnage of our presses can handle your largest RIM parts. Our precise control of reaction chemistry, cure times, and reinforcements means we can meet or exceed your toughest production requirements. Osborne supports its longtime RIM molding expertise with an unwavering commitment to quality:

- SPC methods control all phases of production to ensure defect-free deliveries.

- All incoming RIM material must meet exacting quality tests.

- All RIM parts are fully post-cured under controlled conditions to for optimal physical properties.

- Our quality assurance laboratory provides NIST-traceable measurements for accurate SPC control.

Benefits

The thermosets employed in reaction injection molding create polymer chains that act as strengthening backbones in the molded product, providing excellent properties in extreme temperatures.

Furthermore, RIM molding is suitable for a wide range of thermosets, from structural foams to elastomeric polymers and high-impact and corrosion-resistant polydicyclopentadiene (pDCPD). Osborne has PhD chemists on staff that can help formulate resins to meet specific customer requirements. This means Osborne is not restricted to molding “off-the-shelf” resin formulations.

The low processing temperatures and injection pressures allowed in reaction injection molding mean the tooling investment is often more cost-effective for large parts when compared to injection molding tooling.

RIM’s other cost-saving advantages include:

- Varying wall thickness

- Better economies for lower volume parts compared to injection molding

- Mold-in inserts

- Enables part consolidation when compared to sheet metal

- Tooling that’s usually less expensive than that for injection molding

- Lower labor requirements than resin transfer molding

- Lower energy usage and less need for floor space than injection molding

Altogether, these advantages make reaction injection molding the economical choice, especially for runs of thousands of parts.

Definition

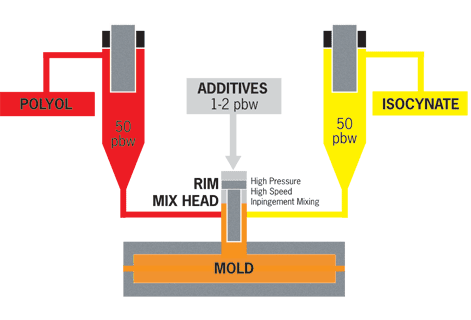

RIM parts are created through a process that begins when two liquid reactants – an isocyanate component and a polyol resin mixture – are held in separate tanks at an elevated temperature with agitators. These liquids are fed through supply lines at high pressure to the mixhead.

When the injection begins, valves open in the mixhead and the liquids enter a chamber in the mixhead at high pressures (usually between 1,500 and 3,000 psi) and high speeds. Here they are mixed by high-velocity impingement. From the mix-chamber, the mixed liquid flows into the mold at atmospheric pressure and undergoes an exothermic chemical reaction, forming a polymer in the mold.

Reaction time is usually expressed in seconds. For extremely large parts the reaction time can be extended to allow for proper filling of the mold.

Equipment

Our reliable, well-maintained RIM molding equipment and durable, low-cost composite RIM molds offer the production flexibility you need for your most demanding projects.

We’re pleased to run a wide range of RIM molding equipment, including:

Reaction Injection Molding (RIM) Machines

Lance Injection Unit

- Capacity: 180 lb/min

- Components: 2

- Ratio: Variable

- Mixheads: 1

Gusmer K-RIM 60

- Capacity: 60 lb/min

- Components: 2

- Ratio: 1:1 w/variable adapter

- Mixheads: 2 or 3 component

Gusmer Delta-RIM 80

- Capacity: 80 lb/min

- Components: 2

- Ratio: Variable

- Mixheads: 2

Gusmer FF-1600 Foam Proportioner

- Capacity: 16 lb/min

- Components: 2

- Ratio: 1:1

- Mixheads: 2

Gusmer Delta-RIM 80

- Capacity: 80 lb/min

- Components: 3

- Ratio: Variable

- Mixheads: 2

Accumetric Meter-Mix

- Capacity: 1.2 lb/min

- Components: 2

- Ratio: Fixed

- Mixheads: 1 (Mechanical)

Admiral 2000 – 2 HP

- Capacity: 300 lb/min

- Components: 2

- Ratio: Variable

- Mixheads: 1

Reaction Injection Molding (RIM) Presses

Cincinnati Milacron 90T WL

- Capacity:90 ton

- Platen:48 x 108-in, tilting

- Open/shut height:72-in / 36-in

- Operation:Manual

Cincinnati Milacron 90T WL

- Capacity:45 ton

- Platen:48 x 79-in

- Open/shut height:84-in / 24-in

- Operation:Manual

Cincinnati Milacron 90T WL

- Capacity:90 ton

- Platen:48 x 108-in, tilting

- Open/shut height:72-in / 36-in

- Operation:PIC Automatic

Osborne-built press

- Capacity:150 ton

- Platen:60 x 108-in

- Open/shut height:56-in / 8-in

- Operation:Manual

Two (2) Cincinnati Milacron 75T WL

- Capacity:75 ton

- Platen:36 x 90-in, tilting

- Open/shut height:54-in / 33-in

- Operation:PLC Auto or Manual

- Frame Rotation Angle:0 to 90 degrees

Osborne-built press

- Capacity:45 ton

- Platen:40 x 56-in

- Open/shut height:47-in / 8-in

- Operation:Manual

FAQs

Injection molding is a process where a thermoplastic polymer is heated to its melt temperature and injected into a mold at high pressure and rapid flow rate. The injected polymer is then cooled to point where the part has enough green strength to be removed from the mold. Reaction Injection Molding is a process where two different liquid polymers are simultaneously mixed and injected into the mold. The two liquid polymers react with one another to form a solid polymer. The reaction between the two liquids is exothermic in nature and requires this excess heat to be removed from the mold during the injection process.

RIM molded polymers have the major advantage of being capable of molding very large parts owing to the ability of modifying the reactivity of the reaction. The extended reactivity allows the polymer to remain in a liquid state longer allowing a large mold cavity to be filled before the chemical reaction is complete. The longer reaction time also creates lower internal mold pressures so that “soft” composite tooling can be used for prototype and lower production applications. The lower internal mold pressure also requires less clamping force to hold the mold closed during the injection process. General internal mold pressures for RIM are 10.3 kPa to 1.4 MPa whereas injection molding will have internal mold pressures ranging from 3.4 MPa to 10.3 MPa.

Typically yes. Most RIM-molded polymers have viscosities between water and a thick syrup whereas melted thermoplastic polymers have a viscosity similar to soft taffy. Thicker polymers, or those with higher viscosities as used in typical injection molding, require heavy and expensive molds and tools to processes, whereas RIM-molded polymers can utilize less expensive aluminum or even composite tools.

Polymers, liquid or semi-solid, with a high viscosity that are injected into a mold tend to create higher internal mold pressures. There is a direct relationship between viscosity and internal mold pressures. Higher internal mold pressures require the mold to be made of higher strength materials such as steel or heat-treated steel. RIM-molded liquid polymers, on the other hand, can be molded in medium-density foam (45 pcf and greater) molds, composite (epoxy, polyester, etc.) molds, and aluminum molds. The injection of low viscosity polymers results in lower internal mold pressures which in turn requires lower-strength (and lower cost) mold materials.

No. There are several factors that determine the best type of mold construction. These factors include the injection rate, the molded part size and configuration, and the peak exothermic temperature of the polymerization process. If the injection rate is too great for the mold size and configuration, internal restrictions within the mold will create back pressures that may be greater than the strength of the material used to construct the mold. Likewise, if the exothermic temperature is too great, the mold surface may begin to deteriorate resulting in poor molded surface quality.

Case Studies

Truck & Trailer Fenders

Molding Process: Reaction Injection Molded (RIM)

Parts Molded: Rear Fenders

Material: Hybrid Polyurethane or DCPD

Color: Black

Part Weight: 14 lbs.

Innovative Answers:

- Flexibility and toughness withstand violent vibrations and impact better than metal

- Molded-in conduit for easy installation of tail light wiring

- Extensive Finite Element Analysis (FEA) and testing used to identify best design and material for this application

- Interchangeable mold logo plates for quick customization

Engine Louver

Molding Process: Reaction Injection Molded (RIM)

Material: Polyurethane

Color: Black

Part Weight: 8 lbs.

Innovative Answers:

- Parts consolidation reduces assembly time and inventory by replacing metal louver, with single piece composite

- Engineered to offer better airflow, cut costs, and simplify installation

- Durability and long life in a harsh agricultural application

Forklift Bumpers

Molding Process: Reaction Injection Molded (RIM)

Material: Polyurethane

Color: Black

Part Weight: 15 lbs.

Innovative Answers:

- Thick, heavy-weight polyurethane cover offers high impact resistance, to protect electrical components on the back of a forklift

- Attractive, molded-in logo and smooth finish achieve customer required cosmetics

Military Truck Fenders

Molding Process: Reaction Injection Molded (RIM)

Material: Hybrid Polyurethane Composite

Color: Black

Part Weight: 13 lbs.

Innovative Answers:

- Impact resistance and strength in all weather conditions with

- Osborne-formulated polyurethane composite

- Meets or exceeds all military tolerances and specifications

- Secondary operations completed with 5-axis CNC router for precise fit and function

Structural Foam Fresh Air Inlet

Molding Process: Reaction Injection Molded (RIM)

Parts Molded: Baffle, housing

Material: Polyurethane structural foam

Color: Light yellow

Part Weight: 1-5 lbs.

Innovative Answers:

- Structural foam gives functional strength and thermal insulation to withstand extreme temperature variations

- Foam density engineered to meet specific load requirements for individual parts

- Self-skinning foam features a smooth and durable finish